Five core servicesEscorting the company's innovative product strategy

-

Process optimization design

Process optimization design

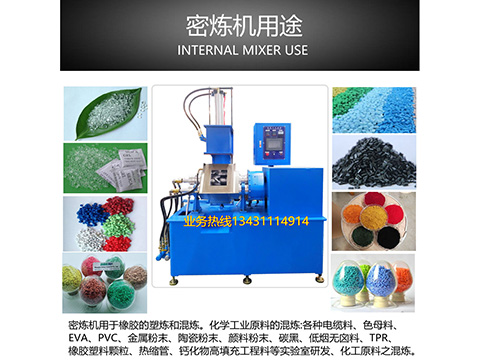

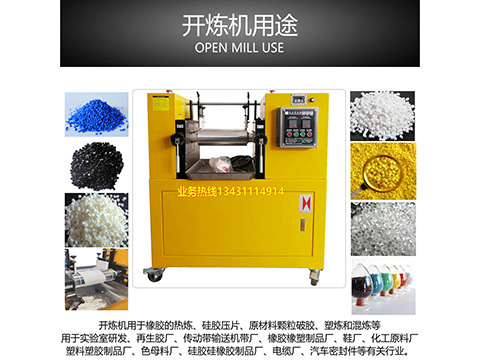

- There are many types of equipment such as small internal mixers, and the process design must be considered comprehensively. It is necessary to be familiar with the process of each equipment to ensure the accuracy of the equipment.

-

Equipment performance optimization and adjustment

Equipment performance optimization and adjustment

- The internal mixer has become the main rubber mixing equipment in the current world rubber industry, which requires optimization and adjustment of various materials and equipment performance.

-

Intelligent transformation and upgrading

Intelligent transformation and upgrading

- The control system of the internal mixer is designed to realize the control of the mixing process of the internal mixer to ensure the efficiency and enhance the competitiveness of the enterprise.

-

Online quality inspection optimization

Online quality inspection optimization

- In the production process, when quality abnormalities are found, the operators are reminded to deal with them in time to reduce waste and improve product quality.

-

Start-up preparation training

Start-up preparation training

- Before starting the machine, check and clean up the debris that hinders the operation of the equipment. The top bolt must be raised before the machine is turned off, and the hopper must be turned back to its position. Close the material door to stop the power failure.

Process flowOptimal design

Process flowOptimal design Equipment performanceOptimization adjustment

Equipment performanceOptimization adjustment IntelligentRetrofit and upgrade

IntelligentRetrofit and upgrade Online qualityDetection optimization

Online qualityDetection optimization Start-up preparationJob training

Start-up preparationJob training